EPC provides high-quality HVOF coatings to protect and improve a components surface properties.

What is HVOF?

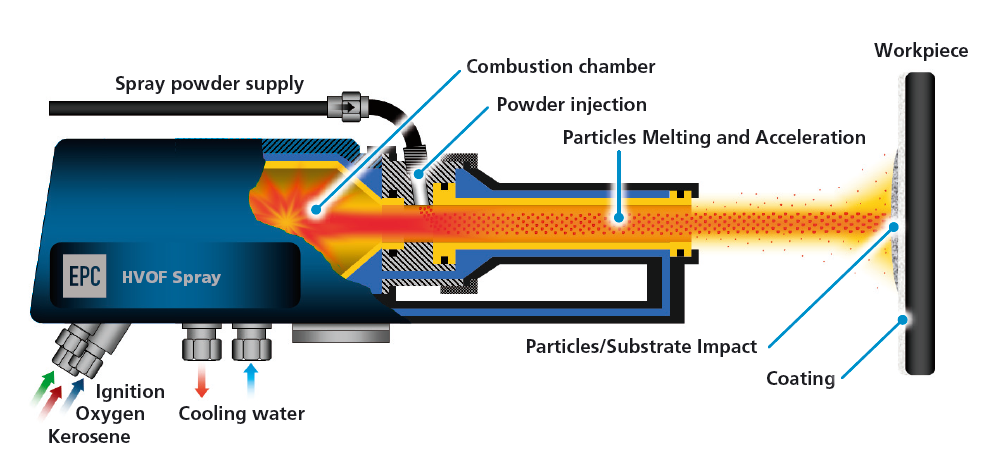

The High Velocity Oxygen Fuel (HVOF) process is when fuel and oxygen are fed into a combustion chamber and ignited and combusted continuously. The fuels can be gases (hydrogen, methane, propane, propylene, acetylene, natural gas, etc.) or liquids (kerosene, Ethanol etc).

The resultant hot gas expands rapidly and exits through a converging-diverging nozzle. The jet velocity produced at the exit of the barrel (>2,000 m/s) exceeds the speed of sound. A powder feedstock is injected into the gas stream at various locations, dependant on the chosen Gun or Torch. It is then accelerated up to approximately 700 m/s.

The jet of hot gas and powder (spray stream) is directed towards the surface to be coated. The powder partially melts in the stream and deposits upon the substrate. The resulting coating has, among other attributes, very low porosity and high bond strength.

A wide variety of materials can be applied using the HVOF process in thicknesses ranging between 0.05mm to a few mm.

Coatings applied via HVOF

Coatings applied via an HVOF process include:

- Nickel-based alloys

- Cobolt based alloys

- Stainless steels

- Stellite, Triballoy, Inconel

- Carbides / Cermets

- WC-Co, Cr2C3-NiCr

- MCrAlY

Applications of the HVOF

Typical applications of the HVOF process:

- High wear conditions (Sliding/abrasion/erosion)

- Corrosive environments (Gases, acids, saltwater)

- High temperature environments (Oxidation)

- Restore thickness on worn components

Benefits of HVOF

There are a number of benefits of HVOF, these include:

- Improved performance

- Improved operational efficiencies

- Reduced costs

Why choose EP Coatings?

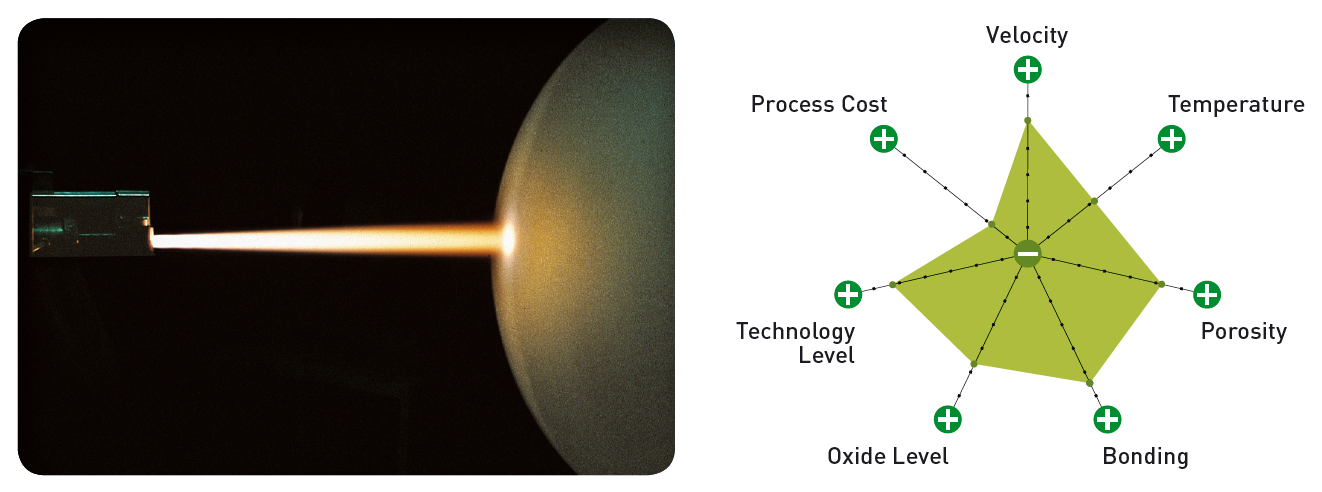

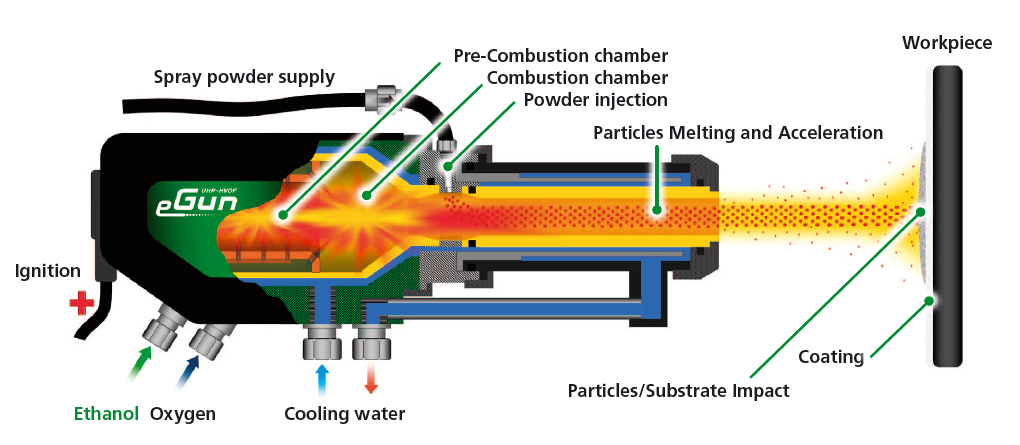

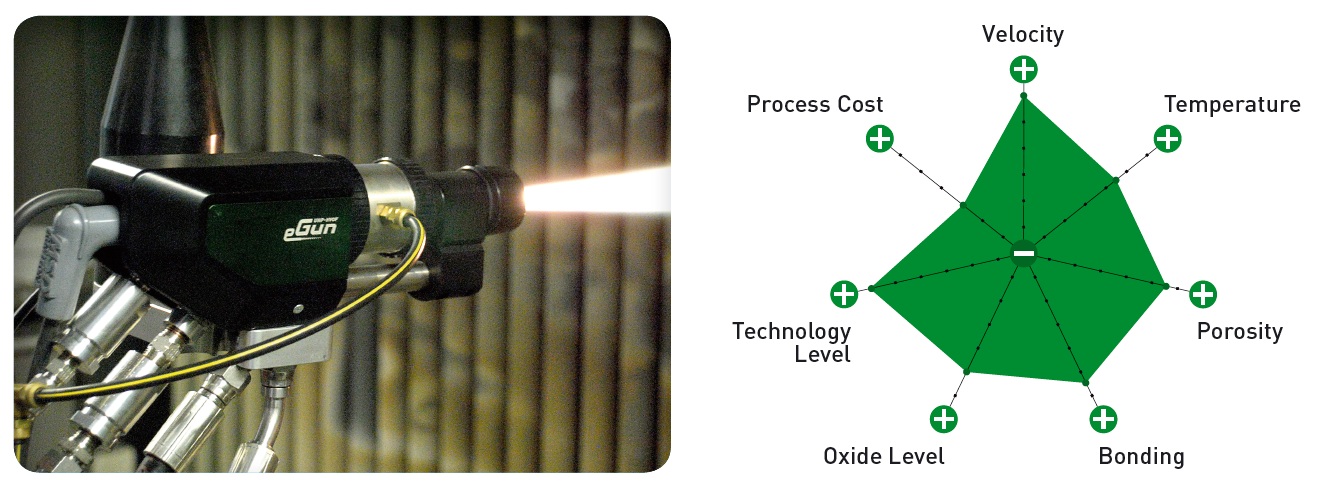

In addition to kerosene-fueled HVOF, EPC also operate the state of the art eGun™. The eGun™ is a liquid fuel HVOF torch that utilizes ethanol as its fuel. The eGun™ is capable of operating at combustion chamber pressures up to 13 bar (188 PSI). This is 3 to 5 bar (43 – 73 PSI) greater than conventional kerosene HP-HVOF systems. It has been shown that higher combustion chamber pressure generates higher flame velocity which in turn generates higher particle velocity. Higher particle velocity results in improved coating density and better overall coating integrity. It is also very easy to run at low flame velocity for slow and hot parameters to produce very good bonding (rough) flash coats.

A wide variety of materials can be applied using the HVOF process, in thicknesses ranging between 0.05mm to a few mm.

Frequently asked question

What are HVOF coating services and how do they enhance component performance?

HVOF (High Velocity Oxygen Fuel) services involve spraying powder feedstock onto components at supersonic speeds to create dense, low-porosity coatings. These coatings deliver exceptional hardness, wear resistance, and corrosion protection—ideal for technical parts exposed to demanding environments.

Which materials can be applied through HVOF coating services?

HVOF coating services support a wide range of coating materials including nickel-based alloys, cobalt alloys, stainless steels, Stellite, Inconel, carbides (WC-Co, Cr₂C₃–NiCr), and MCrAlY. This enables tailored protection for hardness, wear, and high-temperature resistance.

In what applications the HVOF coating services add the most value?

Typical applications that benefit from HVOF services include components subjected to:

- Intense wear (sliding, abrasion, erosion),

- Corrosive environments (e.g., saltwater, acidic gases),

- High-temperature oxidative conditions,

- Dimension restoration of worn parts.

How do HVOF coatings compare to traditional hard chrome plating?

HVOF-based coatings significantly outperform Hard Chrome Electroplating (EHC). Compared to EHC, HVOF exhibits up to 200× less wear loss, greatly improved corrosion resistance, superior impact resistance, enhanced fatigue strength, and better long-term cost-effectiveness.

What is the “eGun™” and why is it a leading-edge offering in HVOF services?

EP Coatings’ state-of-the-art eGun™ is an ethanol-fueled HVOF torch capable of operating at higher combustion chamber pressures (up to 13 bar) than traditional kerosene systems. This generates higher particle velocities and delivers denser coatings with superior integrity and bonding.

Who can apply HVOF carbide in countries like the UK, Europe and North America?

Specialist providers like EP Coatings deliver HVOF carbide spray coatings for clients in both the UK, Europe and the US. With dedicated facilities and global STS Group support, they ensure fast turnaround times and consistent coating quality, wherever your operation is located.

Contact EPC

View EP Coatings list of accreditations and contact us to discuss how our HVOF coating services can help solve your challenges faced by your business or manufacturer.