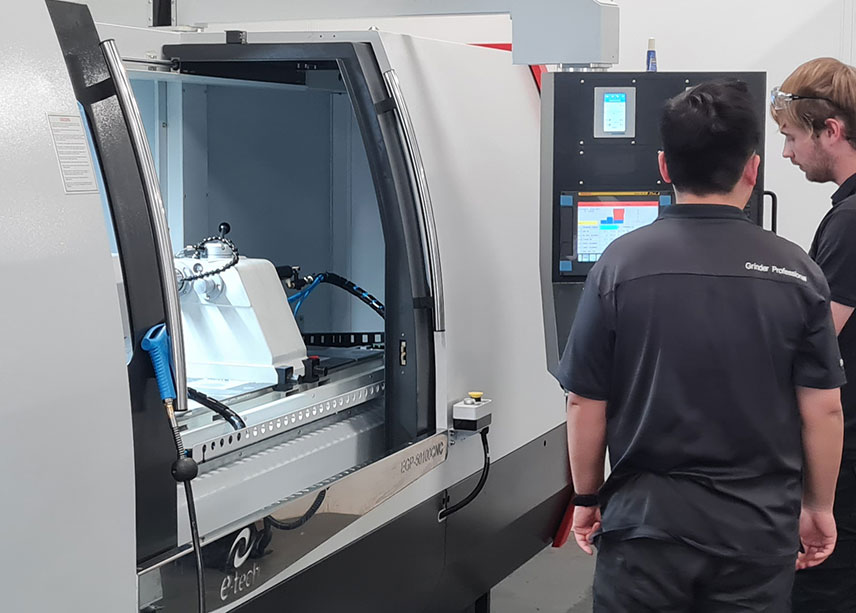

EPC Invests in New CNC Grinding Machinery

We are excited to announce the addition of a new CNC cylindrical grinder at EPC’s Cardiff facility, further adding to the range of coating finishing technologies now available. This significant investment marks an important step in enhancing our capabilities, enabling us to better meet the needs of our ever-increasing customer base within the Aero and Defence sector.

As we continue to expand our footprint here at the Cardiff site, investing in facilities and technology, EPC remains dedicated to leading innovation in the industry, providing exceptional service and expertise within the Thermal Spray Coating industry.

STS Group is excited to participate in the ITSC 2025

The STS Group is proud to be part of the ITSC International Thermal Spray Conference 2025 in Vancouver, Canada, from May 5-8! 🌟 Visit us at Booth #803 to explore our extensive range of thermal spray solutions, including engineered coatings, cutting-edge equipment, consumables, and specialized technical support.

FST, EPC, and Accentus Medical will be showcasing our latest innovations and expertise.

Thermal spray engine coatings: Solve common problems with engines

- Details

The development of engine coatings

There are an estimated 2 billion combustion engines being used worldwide. Whilst many manufacturers are turning their attention to the advancement of electric vehicle technology, there are some manufacturers who understand that the internal combustion engine will remain in service for a long time to come.

Applications of tungsten carbide coatings in the aerospace industry

- Details

What are tungsten carbide coatings?

Tungsten carbide is a chemical compound of tungsten and carbon, which appears as a light grey powder in its most basic form. With an extremely high melting point, tungsten carbide is often used to create thermal spray coatings.

Creating biocompatible coatings for medical devices

- Details

Biocompatible coatings are designed to be compatible with living systems. This means that when a coating is in contact with a living system, it should not trigger a reaction. In the medical industry, it has become increasingly popular to use biocompatible coatings on implants and instruments, to avoid patients having an adverse reaction to these devices.